AFFORDABLE, PRECISION WAX PATTERN 3D PRINTING

If you’re simply trying to keep up with demand or leverage the latest manufacturing techniques while exploring ways to lower production costs, look no further. Skip the silicone rubber mold and shorten your jewelry design-to-manufacturing process by 3D printing detailed yet durable wax patterns quickly.

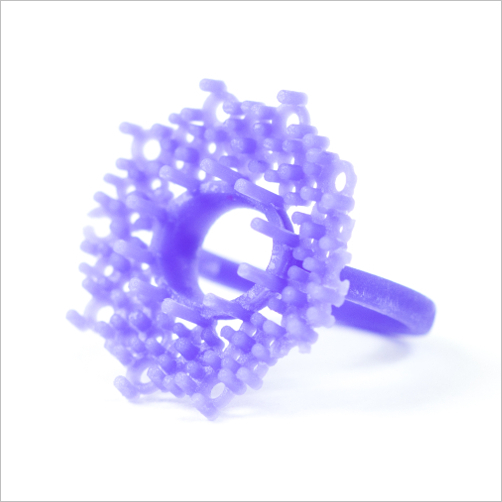

Directly produce high quality, intricate jewlery wax casting patterns with exact, razor-sharp edges, fine feature definition and the smoothest surface finishes to minimize hand finishing. Eliminate tooling time, costs and geometric limitations, and optimize parts and labor costs with automated and efficient processes - from file to finished direct casting pattern.

FAST PRINT SPEEDS – Get up to 10X faster print speeds compared to similar class solutions, with capability for short production runs throughout a work day.

HIGH CAPACITY – With a 3.7X larger build volume capability than alternative similar class printers, gain high productivity and efficiency with 24/7 operation.

BEST CASTABILITY – 100% RealWax™ patterns yield reliable casting performance and deliver high quality patterns with fine feature details. True-to-CAD casting patterns mean you can rest assured parts are accurately and precisely produced the first time.

INTEGRATED SOFTWARE - Streamline your file to part workflow with the advanced 3D Sprint™ software capabilities. 3D Sprint enables you to significantly reduce the cost of ownership of your 3D Systems 3D printer by reducing the need for costly software seats by third party vendors for preparing and optimizing CAD and polygon data.

SIGN UP FOR PROJET MJP 2500W UPDATES